Public utilities and independent power producers commonly use transformer oil derived from naphthenic crude for electrical insulation.

Naphthenic mineral oils are the industry standard, and for good reason. They were a significant improvement over what came before, especially in terms of environmental sustainability.

But the industry standard is no longer the best formulation for safety, reliability and cost-effective transformer maintenance. Read on to learn about the benefits of paraffinic transformer oil.

Why Naphthenic Transformer Oils Have Been the Standard

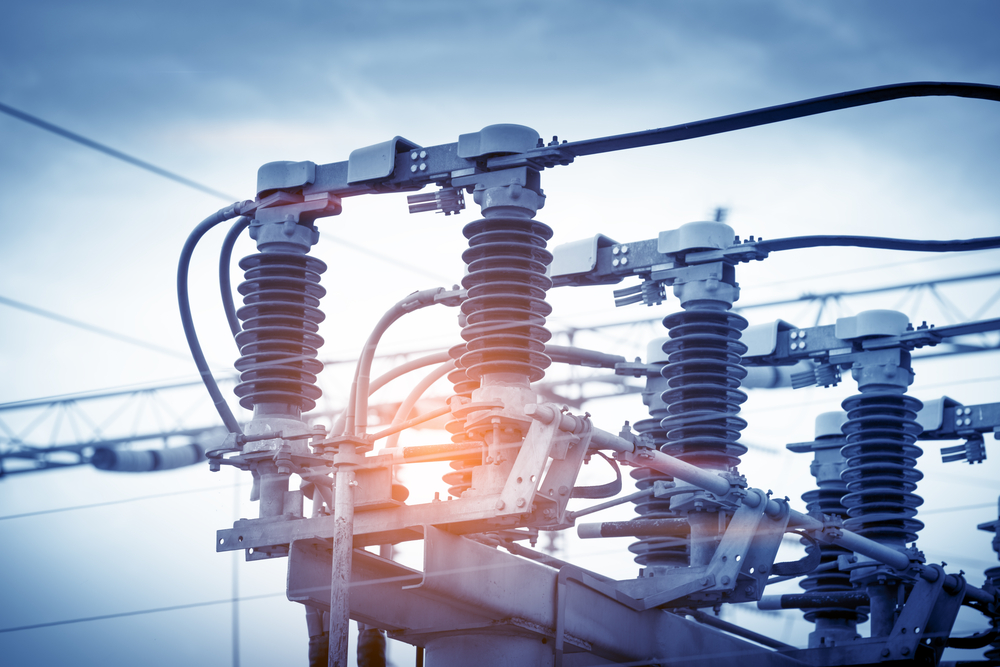

With its naturally low pour point, naphthenic crude makes a decent base for electrical insulating oil. Refined naphthenic mineral oils have long enabled the safe and smooth operation of transformers, switchgear, circuit breakers and rectifiers.

These oils replaced their environmentally hazardous predecessors, which contained polychlorinated biphenyl (PCB). Though PCB aromatics had excellent insulating and cooling properties, the compound is toxic and bioaccumulative in the human body and the ecosystem.

Why There Is Room for Improvement

Naphthenic crude is far from a perfect base oil for electrical insulation, however. It may not pose the environmental and public health risks PCB does, but it contains a lot of aromatics and requires antioxidants to stabilize it for long term use.

You must accept a certain degree of instability with all naphthenic-derived transformer oils. Even after the costly refinement process to remove conductive contaminants, antioxidants must be added to delay oxidation, sludge formation and corrosion.

Naphthenic transformer oil must be frequently tested to identify the telltale signs of contamination:

- Sludge formation – Oxidation forms acids, which in turn alter the chemical properties of the oil and turn it into sludge. This reduces heat dissipation and accelerates the deterioration of your transformer oil’s insulating qualities.

- Corona discharge – Reduced insulation can result in conduction between your transformer and surrounding ionized air. This phenomenon may be common, but it represents power loss and costly inefficiency in power delivery.

- Arcing shocks – Moisture in transformer oil represents a critical risk factor, as it can cause internal arcing that will cause overheating and early failure. It also represents a safety issue if shocks are conducted externally.

By adopting higher standards for transformer oil production and supply, you can reduce the frequency and risk of these phenomena, enjoy more efficient power production and minimize maintenance.

Paraffinic Transformer Oil: A Comparison

As a cleaner, more stable base oil, paraffinic crude provides a superior base for transformer oil with long-term benefits for transformer owners and operators.

Oxidation Stability

Paraffinic crude oil is naturally more stable and less likely to oxidize than naphthenics. Mineral oils derived from paraffinics require fewer antioxidant additives as they are better equipped to resist the chemical reactions that cause sludge, overheating, power loss and arcing.

(In fact, antioxidants may not be necessary at all in paraffinic transformer oil. Specifications have been developed around the requirements of naphthenic crude-based products. In paraffinic T-oil, antioxidants add an extra layer of stability and security to a base oil that already resists oxidation quite well.)

Safety

Another area in which paraffinic oils are superior to naphthenics in electrical applications is their cooling properties. The higher flash point and associated lower volatility exceeds the ASMI specifications created to prevent overheating, keep transformers running and keep their operators safe.

Purity

The paraffinic oils used to make Voltro T-oils have essentially no aromatic content, unlike naphthenics with approximately 30 percent aromatics content. The benefits of eliminating unstable aromatics include color stability, health and safety in handling and most importantly oxidation stability for continuous use.

Considerations

As observed above, naphthenic mineral oil does have advantages. The primary benefit is its low pour point, ideal in cold weather. The disadvantage is in long-term oxidation stability.

To gain the stability advantages of a paraffinic transformer oil, it is important that it is properly refined to achieve a low enough pour point for your regional requirements.

This is why Renkert Oil uses a Group II refining process to produce our Voltro line of electrical insulating oils and achieve all the benefits of a paraffinic mineral oil and the low pour point that meets or exceeds transformer oil specs (ASTM D3487 and Doble Tops).

Why Renkert Oil Is the Best Choice for Your Transformer Oil Supplier

Renkert Oil introduced Voltro to the world in 2013 to provide transformer manufacturers, owners and operators with an oil that was more stable than the industry standard, designed for longevity and superior resistance to oxidation.

We have also invested in a dedicated production facility to ensure Voltro is free of conductive contaminants, whether solid particulates or moisture.

Quality Transformer Oil

As a result of these investments, Voltro oils:

- Meet or surpass rigorous ASTM testing standards.

- Are free of PCB, DBDS, silicone and other biohazards.

- Have a high flash point and lower volatility to help prevent power surges.

- Are extremely clean and low in moisture, well within specs for superior insulation.

- Fully compatible with standard naphthenic based T-oils – allowing commingling.

Superior Service

We also understand that a quality product isn’t sufficient to meet your needs unless it comes with superior service.

- You need our product to remain on-specification between production and delivery. That’s why we work closely with transportation partners with dedicated equipment and experience in preventing contamination.

- For field fills, you need just the right amount of transformer oil. We are logistics experts who will deliver the exact amount to where it needs to go, exactly when it needs to be there.

It’s time to switch from a traditional naphthenic transformer oil to a paraffinic product like Voltro, and to experience the difference in service delivery when you partner with Renkert Oil.

To learn more, just reach out. We look forward to working with you!