Silicone is a wonderfully versatile material for sealant and adhesive makers. But in the midst of an ongoing silicone shortage marked by dramatically rising prices, it’s a tough time to be overly dependent on this particular polymer.

Of course, other industries are struggling right now with the shortage. Makers of pharmaceuticals, cooking utensils, and various types of insulation, to name a few.

Given the unique qualities of silicone that translate into product performance for sealants and adhesives, our customers in this industry are perhaps feeling the pinch the most.

The silicone shortage is a problem that isn’t going away soon. One solution is to extend silicone with a cost-effective product that’s in good supply and maintains product performance: gas-to-liquid isoparaffins.

What’s Driving the Silicone Shortage?

Despite signs that we’re getting on the other side of the pandemic heading into Q2 2022 – from cases dropping to mask mandates lifting – the economic fallout is still with us.

The pandemic sharply reduced demand for silicone products in 2020, leading to sharp drops in production of 15-40 percent. Demand picked back up in Q4 of 2020 but due to limited manpower and logistics issues, supply struggled throughout 2021.

We’re still not out of the woods. Some forecasters even predict the silicone shortage will intensify in 2022 due to China’s production cuts for the core raw material, silicon metal.

In fall 2021, after the world saw a 300 percent spike in prices for silicone due in large part to the related silicon shortage, we attended the Adhesive & Sealant Council annual conference. There, we spoke with customers and colleagues for whom this issue was top of mind.

We were eager to discuss solutions, then and now.

Extending Silicone in Adhesives and Sealants

Silicone’s unique properties are key to product quality in this industry, so manufacturers are understandably skeptical of any reformulation that reduces silicone content.

Some of the essential charateristics of silicone include:

- Keeps elasticity and stability in high and low temperatures.

- Resistant to other chemicals, moisture, and weathering.

- Compatible with more materials than most alternative polymers.

Any material used to extend it must have a high degree of compatibility with silicone to maintain, and not undercut, these properties.

Extending with Shell GTL Solvents

We find that Shell’s line of GTL products acts as an ideal extender for silicone adhesives and sealants.

Correctly formulated, it is tested and proven to extend silicone’s ability to maintain the weatherability of adhesives and sealants, resist moisture, and prevent leakage and shrinkage.

Consistency, Safety, Biodegradability

The properties of these isoparaffinic solvents lend themselves to a consistent, safe, and eco-friendly product formulation for silicone-based products.

Performance and Appearance

- Very low evaporation rate helps maintain product consistency over time.

- Low odor reduces the need for costly additives.

- Low color is ideal for white sealants and transparent applications.

Safety and Environmental Impact

- Low VOC (volatile organic compound) output makes it safe for indoor use.

- Its low skin irritancy is important, especially for adhesive products children might use.

- Its non-toxic and readily biodegradable characteristics meet consumer demand.

Cost-Effectiveness

Because of its high degree of compatibility with silicone and the above performance factors, Shell GTL can often be used in up to 40 percent of the product formulation for a significant cost reduction.

Its compatibility also supports easy replacement of alternative extenders. Shell GTL offers the potential to extend further without losing product quality while increasing cost savings.

At a time when the availability and pricing of silicone are far outside of pre-pandemic norms and will be for the foreseeable future, the promise and plentiful supply of Shell GTL is very good news.

Renkert Oil Is Here to Support You During this Silicone Shortage

As experts with over 40 years of experience in specialty oils and fluids, we’ve seen our customers through periods of economic turmoil before. But not many were quite this challenging.

Thankfully, whether you’re in adhesives and sealants, or in another industry that’s feeling the pinch during this silicone shortage, our ongoing partnership with Shell offers you a game-changing solution.

Shell’s isoparaffinic solvents have offered welcome cost savings to many of our customers. To learn more about extending silicone with GTL in your product formulations or leveraging these products in myriad other ways, reach out to us today.

As a trusted partner in your industry, we’re in this together and eager to help.

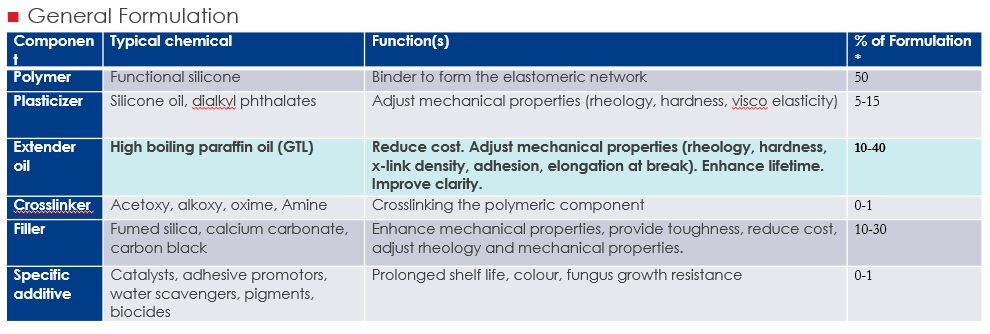

Data table above provided by Shell.