Four decades ago, two people in a barn had no idea their start-up specialty oil business would grow to become an industry leader and one of the largest white oil producers in the U.S.

A lot has changed over the years. The road from supplying re-refined lubricating oil for rubber processing to purifying mineral oil to be suitable for particle accelerator detector fluid had many twists and turns.

What hasn’t changed is our passion for serving just about every market niche with specialty oil products that solve a customer’s problem in an economical way.

You could say it rings our bell.

Suzanne Kingsbury, Director of Quality

1987: Recycled Engine Oil for Rubber Compounding? Good Luck.

In the 1980s, Mike Renkert joined a specialty chemical supply company that served the rubber industry. His interest was in developing a complementary mineral oil supply business with multiple applications in mind.

One opportunity he saw was to offer re-refined engine oil for rubber inner tubes. The recycled engine oil performed brilliantly. At a time when “sustainability” was not a commonly used term, particularly in this industry, Mike’s embrace of re-refined oil led the field.

Although the three-year trial to develop a complementary process oil business was a success, Mike never got full buy-in support of his specialty oil vision, so he and the company amicably parted ways.

In 1987, he decided to start his own company. In a converted barn on Mike’s farm in Chester County, Pennsylvania, Renkert Oil was born. The first customers were very supportive, and Renkert Oil was off and running.

A portrait of the original site of Renkert Oil, at what is today French Creek Golf Course, hangs above the fireplace today in our office in Morgantown, Pennsylvania

Every sale was hard-won in the beginning. Whenever Mike or his long-time assistant, Bonnie Stoltzfus would take an order, they would celebrate by picking up a handbell and ringing it—loud and proud!

It turned out Mike was right. The rubber process oil market was an area he could thrive in. His initial entry using re-refined oil introduced him to customers and suppliers, too.

But he was far from done.

Pretty soon manufacturers were asking Mike how to solve other problems, leading Mike to develop relationships with all the major oil refiners. Adding salesmen and products for automotive tires and rubber roofs came naturally.

Several years later, Mike learned about a new refining process that produced unusually pure products. So, he positioned Renkert Oil to capitalize on its industry reputation and these new, better oils. Taking pilot plant-produced samples, he pre-approved this new, quality oil to meet new needs before the refinery updates were completed.

1999: A New Era for White Process Oil — Group II & III Isoparaffins

A dozen years of success prepared Renkert Oil for its next big step—Renkert Oil was chosen as Chevron’s U.S. process oil distributor for its highly refined, low volatility, water-white ParaLux mineral oils. Mike’s proactive customer approvals for ParaLux process oils made Renkert Oil the natural choice.

The industry was changing at this time. Chevron introduced this new Group II technology to develop super high-quality mineral oils.

“Traditional Group I refining used a mechanical process. They would refine petroleum crude oil and remove unwanted aromatics with a solvent, then cool down the remaining oil so a filter could remove any wax as a byproduct. It was a complex process, and you had to have a really good crude oil to start with,” explained Mark Proudfoot, Senior Vice President and Chief Technical Officer for Renkert Oil.

Sales meeting in San Antonio, Texas

In contrast, the new Group II method was done with all catalytic hydroprocessing. No solvent was needed to remove aromatics, and there was no cooling, mechanical filtering, or wax byproduct. The result was a better quality, dewaxed isoparaffinic mineral oil.

Mike recognized that this line of water-white products with excellent properties for process oil applications was the future. He was determined to develop Renkert Oil’s supplier relationships to better serve the market with this white oil.

He developed the market for ParaLux process oil in rubber compounding. This was ideal for manufacturers of light-colored, synthetic rubber products who needed process oils that were more color-stable than traditional oils.

This was the start of Renkert’s industry slogan, “We put the soft in soft-touch.” The ParaLux extender oil softened TPEs and rubber compounds while allowing light and vibrant colors.

The greatest compliment we ever receive from our customers is when they tell us we’re “easy to do business with.”

Mike and his vice president, Mark Proudfoot flew to Finland in 2003 to meet with Neste Oil to secure a supply of its Group III mineral oils. An even higher quality base oil, it was so pure that they recognized its potential for food-grade applications.

As Mark recalls, the Neste Sales and Development manager, Henrik Holmqvist told them, “We like the way you Americans think. I think we can work together.” As a result of that meeting, Renkert Oil became more than a buyer—it became the sole U.S. distributor for Neste Oil.

Meanwhile, Renkert Oil’s relationship with Chevron continued to grow. In 2006, we became Chevron’s European process oil distributor and opened Renkert Oil Europe in Antwerp, Belgium. Today, we represent around 90 percent of all ParaLux sales around the world.

There was still plenty of work to be done to advance the mineral oil industry back home.

2007: White Oils, Neutrino Detection and Other Technical Applications

In 2007, we opened a facility in the Chicago area with equipment that allowed us to process highly refined mineral oil into food-grade white oil. We also opened another new facility at Wolf Lake, in Hammond, Indiana in 2008 to develop new white mineral oils for technical applications.

The Wolf Lake facility included special mixing equipment featuring an advanced Pulse Air system. Using nitrogen, the system rapidly blends and “dries” mineral oil by thoroughly removing water vapor.

This capability would soon be important to U.S. government researchers.

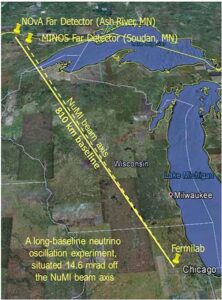

Fermi National Accelerator Laboratory (Fermilab) was working on the NOvA experiment to study neutrinos, tiny particles that can pass through matter. A beam of neutrinos was to be sent 500 miles through the earth from the Fermi accelerator in Batavia, IL to a massive detector in Minnesota measuring 50 feet wide, 50 feet tall, and 200 feet long.

Mineral oil played a key role in the large detector as the medium through which the neutrinos would pass, allowing photocells to measure particle collisions. Fermilab needed an extremely pure, high-clarity white oil carefully blended with wave shifter powders and solvent for this. And they needed a lot of it—3 million gallons.

- Massive NOvA far detector in Ash River, Minnesota filled with Renkert Oil-produced scintillator fluid based on our high-purity mineral oil and Fermi supplied components

- The path of the neutrino beam from Batavia, IL to Ash River, MN

- The scintillator fluid glows in the sunlight due to wave shifter powders and pseudocumene solvent

Fermilab compared the best white oils from all the major refiners and selected Renoil 70-T as the highest purity and best suited to this application. This three-year project began deliveries of Renkert-produced scintillator fluid in 2012. The NOvA project is still ongoing with Fermilab gathering important data to advance the field of particle physics.

The technical requirements of this contract demonstrated our ability to engineer extremely pure, dry mineral oils that could be used in other applications as well, such as our VOLTRO® electric insulating oil, a.k.a. transformer oil.

We have continued to research applications of electric insulating oil to this day. New uses of mineral oil include immersion cooling in emerging technologies such as crypto mining, data centers, electric vehicles, and more.

Renkert Oil continued to grow and thrive adding experienced salesmen, operations and finance personnel. In 2010, Nick Livanos joined Mike Renkert and Mark Proudfoot in the ownership team.

Logistics & Finance Team Meeting at Top Golf

2018-2025: Pushing the White Oil Industry Forward — As the 3rd Largest U.S. Producer

No matter how much Renkert Oil has grown, Mike hasn’t forgotten where he came from. Though we do have larger contracts, this is still a small business at heart, eager to serve large and small businesses.

Packaging

Opened in 2018, our packaging facility at Wolf Lake has allowed us to provide smaller quantities of mineral oil to support entrepreneurs, startups, and boutique resellers. At the time of writing, we are expanding packaging in a second facility as well.

Safe Quality Food

We’re also doing our part to raise the bar for quality in the white oil business, adding SQF (Safe Quality Food) certification for three of our white oil production facilities in 2019. Based on ISO 9001 with added attention to food safety, SQF is an internationally recognized standard that exceeds FDA requirements for food-grade white oil.

Cosmetics & Shell GTL

This bar-raising drive led Renkert Oil to become the North American distributor for Shell GTL solvents in 2020. Pure and readily biodegradable, these products have helped our customers create better products, such as silky-smooth, safe, eco-friendly cosmetics.

Agriculture & Organic Farming

Our food-grade mineral oils have been useful in various agricultural applications, such as grain dust control and as an anti-clumping agent in animal feed. In 2022, Renoil PSO 70 was approved for use in organic farming as an insect-suffocating Paraffinic Spray Oil, a safe alternative to pesticides.

Medicine & Food Supplements

In 2024, we added USP (U.S. Pharmacopeia) Verified™ to our list of white oil certifications. This has allowed our customers in medicine and food supplement manufacturing to bear the USP Verified Mark representing the highest purity and safety standards.

Ecovadis Bronze Medal for Sustainability

We also earned recognition from Ecovadis, a world-leading organization in advancing sustainability, for our conservation efforts. Our Bronze Medal rating puts Renkert Oil in the top 35 percent of rated companies working to advance supply chain sustainability goals.

However, it isn’t our awards or certifications that we’re most proud of. The greatest compliment we ever receive from our customers is when they tell us we’re “easy to do business with.”

Behind everything we do, that’s what drives us.

Renkert Oil: Dedicated to Every Customer, Every White Oil and Process Oil and Base Oil Application

Mike Renkert started Renkert Oil in 1987 because he saw a need in the market that he was eager to serve, and he loved the business enough to do it right.

- Mark Proudfoot, Vice President and Chief Technical Officer

- Nick Livanos, Vice President and Chief Financial Officer

- Suzanne Kingsbury, Director of Quality & Marketing

That’s what drew Mark Proudfoot (2000) and Nick Livanos (2010) to join him as co-owners, Suzanne Kingsbury to become our Director of Quality, and the dozens of customer service and sales professionals who have joined our team over the years.

Sales meeting in New Orleans, Louisiana

Despite the company’s growth, it has remained a family-like environment. Every member of the team is confident in Renkert Oil’s capabilities:

- Wide Selection—specialty oils for virtually every industry and niche application

- Research & Development—partnering with customers to develop exciting new products

- Deep Inventories—a strong investment in stocking high-demand oils

- Redundant Supply Points—facilities across the U.S. with redundant supply

- Logistics Excellence—systems and expertise to deliver on-time and on-budget

We might not ring a bell anymore when orders come in, but the team Mike has built is just as excited to earn your business today as he’s been since the beginning.

“We’re going to continue to keep the focus on our customers and make sure they’re satisfied. That’s the way to stay in business,” Mike said. “And as long as we’re in business, let’s keep considering new opportunities to fill needs in the market. And let’s have some fun.”

Mike Renkert, Founder/Owner

Discover for yourself the Renkert Oil difference. Contact us to learn more about making us your supplier of choice for white oils, isoparaffins, process oils, base oils, and much, much more!